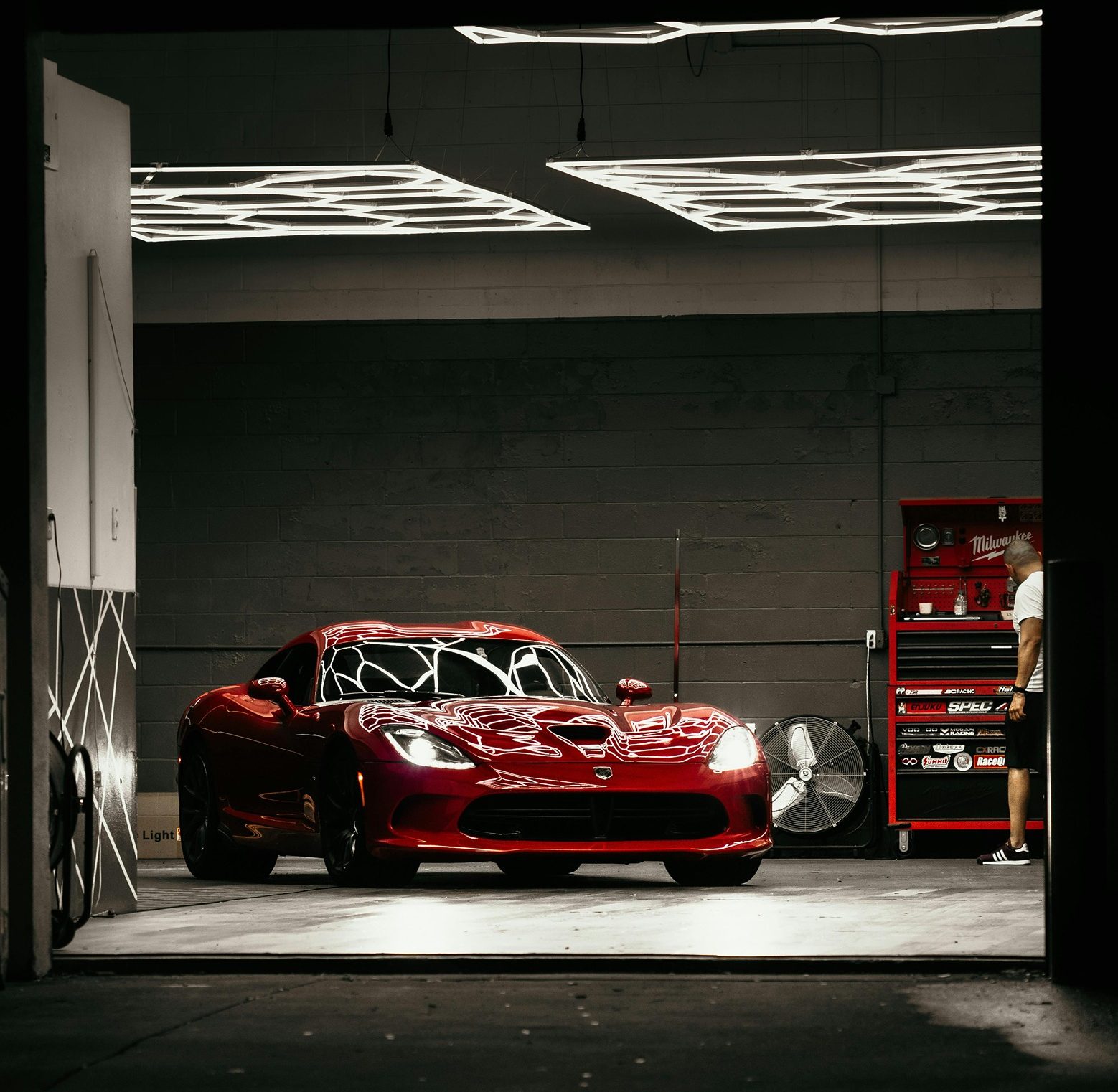

Hey there, fellow Socket Diggers! When it comes to setting up your garage, one essential piece of kit stands tall among the rest: the mighty toolbox. But with so many options out there, how do you pick the one that’s right for you? Fear not, because we’ve got your back with some down-to-earth advice on selecting the perfect toolbox selection for your blue-collar kingdom.

Toolbox Selection:

- Size Matters, Mate: Before you even think about diving into the sea of toolboxes, take a good, hard look at your garage space. Got a corner crying out for some organization? Or maybe you’re blessed with acres of workspace? Whatever the case, make sure you measure up and choose a toolbox that fits like a glove. You don’t want to be tripping over a monster-sized chest every time you reach for a wrench. Consider not only the physical dimensions of your garage but also the layout and your specific needs. If your garage doubles as a workshop and parking space, optimizing the available space becomes even more critical. Additionally, think about potential future expansions of your tool collection. It’s wise to invest in a slightly larger toolbox than you currently need to accommodate future growth.

Toolbox Material:

- Material Matters: Steel, plastic, aluminum – oh my! When it comes to materials, each has its pros and cons. Steel is tough as nails but can rust if you’re not careful. Plastic might not be as rugged, but it’s lightweight and won’t rust. And aluminum? Well, that’s the middle ground – strong, lightweight, and corrosion-resistant. Think about what kind of abuse your toolbox will face and choose accordingly. Delve deeper into the advantages and disadvantages of each material. For example, elaborate on the different types of steel commonly used in toolboxes and how they affect durability and weight. Discuss specific scenarios where one material might be more suitable than another, such as environments with high humidity where rust resistance is crucial. Additionally, provide real-world examples or testimonials from users who have experienced the benefits or drawbacks of each material firsthand. Understanding Metal Types and Their Uses – This article provides detailed information about different types of metals commonly used in toolboxes, helping you make an informed decision about material selection.

Check out our Top 3 Tool Box Picks!

|

About this item

|

||

|

About this item

|

||

|

About this item

|

Toolbox Components:

- Drawers and Compartments Galore: Ah, the sweet sound of drawers sliding open and shut. When choosing your toolbox selection, think about how many compartments and drawers you need. Are you a neat freak who likes everything in its place, or do you thrive in organized chaos? Either way, make sure your toolbox has enough storage options to keep your gear sorted and accessible. Discuss various storage configurations commonly found in toolboxes, such as shallow drawers for small hand tools and deeper compartments for power tools or bulky items. Provide tips on how to optimize drawer layout for maximum efficiency, such as organizing tools by type or frequency of use. Additionally, explore innovative storage solutions, such as removable dividers or customizable foam inserts, that allow users to tailor their toolbox to their specific needs.

Toolbox Mobility:

- Mobility Matters: Unless you’ve got the biceps of a Greek god, chances are you’ll want your toolbox selection to be mobile. Look for models with sturdy wheels that can handle rough terrain – because let’s face it, your garage floor probably isn’t a smooth, polished paradise. Bonus points if your toolbox comes with a handle for easy towing. Who needs a gym membership when you’ve got a toolbox selection to lug around? Discuss the importance of mobility not only within the garage but also for transportation to job sites or other locations. Highlight features such as ergonomic handles and rugged wheels that make it easy to maneuver the toolbox over uneven surfaces or up and down stairs. Consider including advice on maintaining mobility components, such as lubricating wheel bearings or replacing worn-out casters, to ensure long-term usability.

Toolbox Budget:

- Budget Blues: Last but not least, let’s talk cold, hard cash. Toolboxes come in all shapes and sizes, and so do their price tags. Set yourself a budget and stick to it like glue. Sure, that top-of-the-line, diamond-encrusted toolbox might be tempting, but do you really need all those bells and whistles? Be smart with your money and invest in a toolbox selection that’ll get the job done without breaking the bank. Provide guidance on how to determine a reasonable budget based on factors such as the size of your tool collection, the frequency of use, and your long-term goals for your garage setup. Discuss cost-saving strategies, such as buying used or refurbished toolboxes or opting for simpler designs without unnecessary features. Additionally, offer tips on prioritizing features based on their importance to your workflow, such as prioritizing durability over aesthetics or prioritizing storage capacity over mobility.

So there you have it, folks – a crash course in toolbox selection for the blue-collar warrior. Whether you’re a weekend warrior or a seasoned pro, the right toolbox selection is crucial for keeping your gear organized and your sanity intact. So go forth, my friends, and may your wrenches be forever at your fingertips!